Cargo bikes 101 - How To Choose The Right Electric Cargo Bike For Your Commercial Fleet

If you are convinced that electric cargo bikes are the way to go for your fleet, congratulations! Electric cargo bikes are ideal for most commercial fleets but did you know that they are not all created equal?

As you might have learned in the first article of our Cargo Bikes 101 Series: Why Electric Cargo Bikes Are Perfect For Your Last-Mile Fleet (if you haven’t read it yet, you can do so now), cargo bikes come in all shapes and forms, making them more or less adapted to your specific use case.

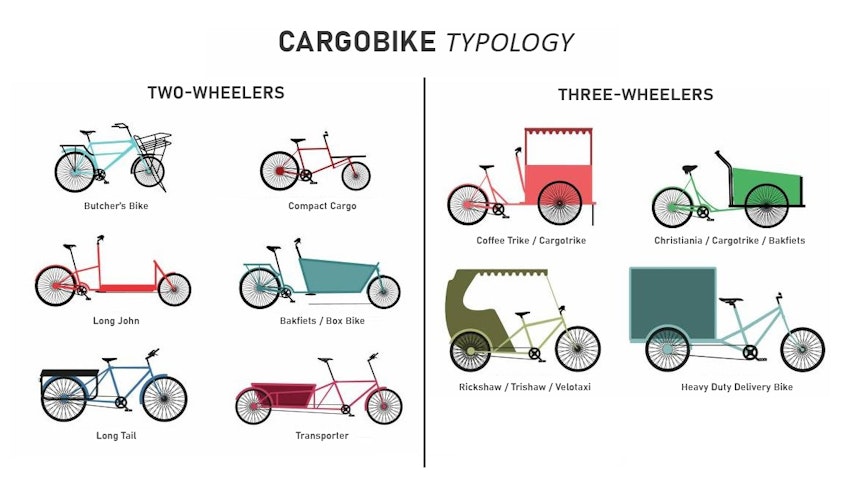

There are two-wheelers, three-wheelers, and even four-wheelers, as well as butcher's bikes, heavy-duty delivery bikes, and many more… They can be front or back-loaded, and the differences between them are significant. The cargo bike you choose for your fleet must answer your fleet's specific needs to be an effective solution for your operations.

Most fleet managers start by considering a body type or brand they heard about or saw in the street or online, thinking it would be a great fit for them, without going into the nitty-gritty specification details. While this may be a quick and easy way to get started, it's not the best way to ensure the long-term success of your fleet. If you want your fleet to work for you, you need a more strategic approach…

But fear not, it doesn’t have to be complicated. We will guide you through this!

TL;DR - find our cheatsheet to choose the perfect electric cargo bike for your fleet at the end of this article.

Source: https://www.bleeperactive.com/blog/bike-to-work-for-cargo-bikes

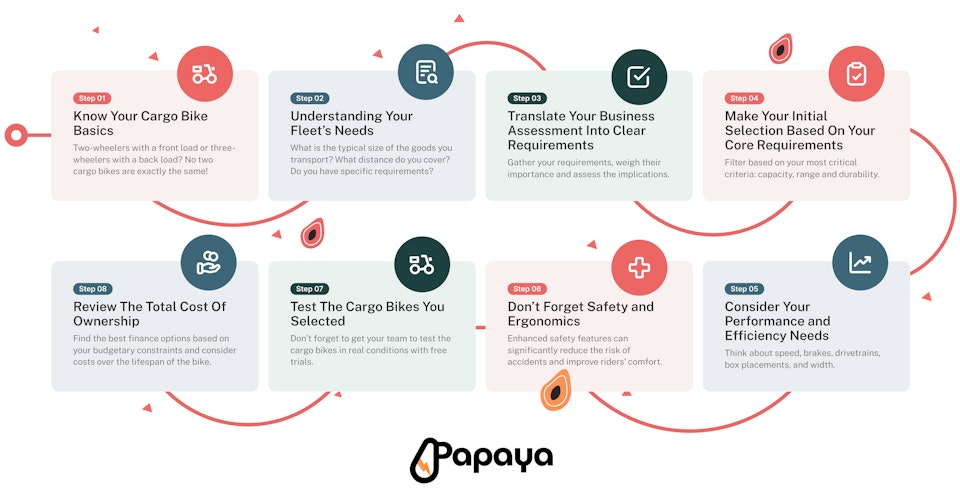

Step 1: Know Your Cargo Bike Basics

It is important to understand the variety of cargo bikes currently available in the market. This will help you realise why it is critical to not solely focus on one particular type, but to consider all your requirements. Doing so will provide you with a solid foundation to build upon. If you are unsure of what we mean, we recommend checking out the first article in our "Cargo Bikes 101" series: Why Electric Cargo Bikes Are Perfect For Your Last-Mile Fleet!

Step 2: Understanding Your Fleet’s Needs

When it comes to integrating electric cargo bikes into your commercial fleet, it's crucial to thoroughly evaluate your specific needs and requirements. Selecting the right bike can significantly impact your fleet's efficiency, productivity, and overall success. It is therefore extremely important to align the bike's capabilities with your unique operational requirements.

Below are the key factors to consider when determining your fleet's needs.

What is the average size and weight of the cargo or goods you transport?

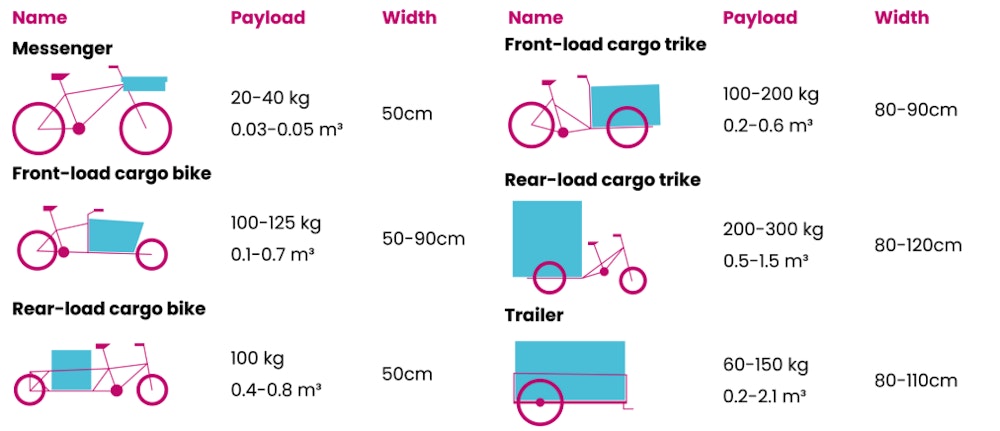

The capacity required for electric cargo bikes greatly varies depending on your business and industry. These bikes come in different body types, frames, and cargo box placements, among other factors that impact their capacity. To ensure they can handle your typical load sizes, select electric cargo bikes based on their payload capacity. Some bike models can carry up to 250kg of load, but be careful, as they might be trickier to manoeuvre.

What distance does your fleet typically cover in a day?

This will dictate the range you must consider for your electric cargo bikes. Consider the battery life and charging options, as these factors directly impact your ability to operate continuously without interruptions. Opting for bikes with long-lasting batteries or swappable battery systems can maximise your fleet's uptime. Keep in mind that the range of electric delivery bikes also depends on their loads, the number of stops, the landscape and weather temperature, or even the braking system. Heavy loads, many ascents and cold weather can cut the driving range significantly. Most electric cargo bikes have a driving range between 40km and 100 km on a single charge.

What is the topography of your operating area?

If you often encounter steep hills or challenging terrain, prioritise electric cargo bikes with sufficient motor power and torque to handle these conditions. Additionally, if you need to navigate through narrow streets or have limited storage space, you should consider the bike's physical dimensions.

Do your cargo or goods require specific transportation requirements to ensure their safe delivery?

Consider whether you need additional features or modifications depending on your industry and specific operational requirements. This could include cargo compartments with temperature control for food delivery, secure lock systems for valuable items, or customisable storage options to accommodate specialised equipment.

What are your durability and maintenance requirements?

Do you have in-house mechanics you can rely on or do you need external service providers? Consider the availability of service and maintenance support from the manufacturer or local bike shops to ensure prompt and efficient repairs or servicing when needed. Look for bikes with robust frames, high-quality components, and reliable braking systems to withstand the demands of daily use.

Do you use a specific Fleet Management System?

If you do, you will need to consider the compatibility of the electric cargo bikes with your existing tools. Alternatively, you may consider using software that accommodates cargo bikes, such as Papaya.

Do you have a maximum budget available?

Make your calculations based on your margin profile and don’t forget to consider the Total Cost of Ownership.

What vehicle mix you are trying to achieve?

You don't have to switch your entire fleet to cargo bikes all at once. You may want to keep other types of electric vehicles for specific operations or areas. Keep this in mind while assessing your fleet.

By carefully evaluating these factors and aligning the capabilities of the electric cargo bikes with your fleet's unique operational requirements, you can maximise efficiency, optimise delivery processes, and ensure a smooth integration of the bikes into your commercial fleet. Ultimately, choosing the right electric cargo bike is a crucial step towards achieving sustainable and effective transportation solutions for your business.

Step 3: Translate Your Business Assessment Into Clear Requirements

Summarise your answers to the questions in step 2 and consolidate them to identify your most important criteria. Your new cargo bikes must meet the established criteria in order to be suitable for your fleet, taking into account your constraints. Make sure to weigh your criteria to easily identify must-haves from nice to haves.

Step 4: Make Your Initial Selection Based On Your Core Requirements

Now, it is time to consider the most critical e-cargo bikes’ specifications. This will help you do a 1st filtering of the best options you have available for your specific use case. Review the assessment you just did and use it to select only the cargo bikes that answer these specific needs.

Capacity: by now you should have a good understanding of the average weight and size of the loads your vehicles usually handle.

Range, battery life and charging options: based on your assessment, you should have a rough idea of the distances your electric delivery bikes will need to travel daily. Consider the battery life, how long it takes to charge and make sure the batteries are easily swappable. Keep in mind that with integrated battery your cargo bike will have to stay put for charging for extended periods of time.

Durability and maintenance requirements: Cargo bikes are generally easy to maintain and durable. However, it's important to consider the availability of spare parts and whether service providers have expertise with the specific brand and/or model. If the cargo bike you choose is too niche, you may struggle to maintain it effectively, resulting in higher costs and lower vehicle availability.

Step 5: Consider Your Performance and Efficiency Needs

Once you have a first shortlist, it's time to move on to the second layer of criteria: evaluating the performance and efficiency of the electric cargo bikes you selected.

Motor power, torque, speed and acceleration: this is critical, especially if the topography of the places you operate in is hilly. It is also important to consider the country you operate in as they might have different speed limits (25 km/h in the UK, Europe and Australia; around 32 km/h in the US).

Brakes: When carrying heavy loads or making frequent stops, it's important to have good brakes. Cargo bikes require extra braking power to stop safely with heavy cargo. The most common type of brake for cargo e-bikes is disc brakes, which are powerful and reliable in all weather conditions. There are two types of disc brakes: mechanical and hydraulic. Hydraulic brakes offer superior braking power and control, and last longer than mechanical brakes. Some e-bikes also use regenerative braking to extend the battery's life and increase the driving range.

Drivetrain: The drivetrain is basically all the machinery that makes your bike move forward. The drivetrain determines how easy it is to ride the electric delivery bike and how well it handles different surfaces, ascents, heavier loads, etc. Again considering the topography of the places you operate in is essential. There are three main types of drivetrains used in e-cargo bikes: chain, belt and chainless.

Chains are the most common type. They require regular cleaning and lubricating and must be replaced every 1000 km or so.

Belts usually last longer and require less maintenance. They work with internal gears and offer a smoother pedalling experience.

Chainless uses no chain or belt, making chainless bikes lighter and more flexible. Having fewer moving parts than regular drivetrains, they offer the smoothest riding experience, less maintenance, and a longer lifetime.

Cargo box placement: They are important as they determine the centre of gravity, weight distribution and ease of loading of your cargo bike. There is no right or wrong answer to whether it’s best to have the box in the front or in the back but it will depend on a sum of different factors, e.g. the wheelbase and bike’s body type, rider’s range of vision, etc.

For example:

Two-wheelers with a cargo box on one end are generally less stable than three-wheelers with a low-set box. They are also capable of handling less weight.

A front-mounted cargo box can be stable and easy to load, but it can only fit a limited amount of cargo before it starts obstructing the rider's view.

Width: If you plan to ride your electric cargo bike on bike lanes or narrow streets, be sure to review its dimensions. Most cargo bikes are less than 1 meter in width and are therefore considered conventional bikes. However, if a cargo bike exceeds 1 meter in width, special rules apply and it must have reflectors and position lights on the front or rear trailer.

Step 6: Don’t Forget Safety and Ergonomics

When selecting commercial electric cargo bikes, it is crucial to prioritise safety and ergonomics. These two factors play a vital role in ensuring the well-being of both riders and cargo. By choosing bikes with enhanced safety features, the risk of accidents can be significantly reduced. Additionally, focusing on ergonomic design helps to promote riders’ comfort and prevent potential health issues caused by prolonged use.

Stability: The shape and weight of your loads might impact vehicle stability. Some cargo bike shapes might be more or less adapted to specific types of cargo. By considering stability as a key factor in the decision-making process, you can enhance overall safety, reduce potential damages, and ensure a smoother and more reliable delivery experience for your operations. More stability allows for better control and manoeuvrability, especially when navigating through challenging terrain or crowded urban areas.

Visibility: Always consider how your cargo will fit in the cargo area and make sure that it would not impede your field of vision.

Weather protection: Your drivers will likely spend a significant amount of time driving the commercial electric cargo bike you have selected. Ensure that the cargo bike offers sufficient weather protection, particularly if you operate in areas with difficult weather conditions, such as heavy rain, snow, or high temperatures. If you are carrying fragile goods, also make sure that the cargo bike provides sufficient protection.

Sufficient lights: Lights are also essential to maintain visibility in difficult conditions.

Theft Protection: While regular bike locks are a common choice for locking cargo bikes, they may not be the most convenient option when making many short stops, and may not offer the best protection against thieves. Consider easy locking system as well as more advanced locking options, GPS, and other types of tracking devices to increase protection. Additionally, review how your load would be protected, especially if you carry valuable goods.

Step 7: Test The Cargo Bikes You Selected!

This sounds obvious but one of the most critical steps is testing the shortlisted commercial electric cargo bikes before making a final decision. They might be perfect on paper but you should check if they live up to this in real life. You need to assess the bikes' performance, handling, and overall suitability for their specific needs.

Make sure to involve fleet operators, riders and other stakeholders in the evaluation process. Their input and feedback will provide valuable insights into comfort, usability, and any specific requirements they may have. By involving the key individuals who will be using the bikes on a daily basis, fleet operators can make more informed decisions and ensure that the chosen electric cargo bikes align with their fleet's unique operational demands.

An effective approach is to arrange demos or trial periods with bike manufacturers or suppliers. Many of them offer one-week trial packages. This hands-on experience allows fleet operators to test the bikes under real-life conditions, evaluate how they handle in different terrains, carry intended payloads, and integrate with existing fleet operations. One of Papaya’s customers conducted a trial on the Soho streets in London, and this was the key criteria that led them to decide to purchase a certain type of cargo bike.

Step 8: Review The Total Cost Of Ownership

Addressing the financial aspects of acquiring and maintaining commercial electric cargo bikes is a critical step in the decision-making process.

Evaluate the initial purchase cost of the electric cargo bikes and compare them with the value they provide in terms of efficiency and operational benefits.

Research potential incentives or grants that may be available to offset some of the upfront costs

Take into account the operational expenses associated with charging infrastructure, maintenance, and repairs. Understanding the long-term maintenance considerations, such as the availability of spare parts and local service providers, is essential for ensuring a smooth and cost-effective ownership experience.

Calculate the total cost of ownership over the expected lifespan of the bikes - considering factors like depreciation, energy consumption, and potential savings in fuel and maintenance costs.

Purchase is not your only option! Consider renting or all-inclusive leasing options, it can be a great way to test if your chosen cargo bike is truly the right fit before purchasing them (if purchasing is required at all).

By carefully reviewing the financial aspects and considering the total cost of ownership, fleet operators can make well-informed decisions that align with their budgetary constraints and long-term business goals.

How to Effectively Research and Compare Available Options

When it comes to selecting the right commercial electric cargo bike for your fleet, conducting thorough research is crucial and is the key to finding the perfect commercial electric cargo bike that will optimise your fleet's performance and contribute to your business's success. We recommend:

Exploring websites, product catalogs, and technical specifications to understand offerings and features.

Reading reviews and testimonials from other fleet operators who have already implemented the cargo bikes you are considering into their operations. These real-life experiences can provide valuable insights into the bikes' performance, durability, and overall satisfaction.

Seeking recommendations from industry peers, attending trade shows or conferences, and engaging with online forums or communities dedicated to sustainable transportation.

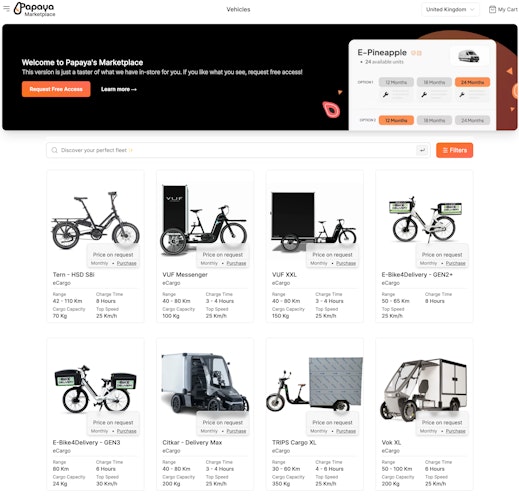

Using Papaya’s Marketplace. It is the easiest way to access a wide selection of electric cargo bikes and find all the specifications you need to make informed decisions, all in one place. It allows you to:

compare multiple e-cargo-bike models.

filter them based on your requirements such as range, capacity and price.

access different package options, ranging from purchase to renting and all-inclusive subscriptions. You choose the option that suits you best, minimising the financial risk.

find service providers to assist you with any add-ons, such as maintenance, IoT, or insurance. This will give you a better idea of your total cost of ownership from day one by including all of these services at the point of purchase.

identify which suppliers offer demos and trials and receive help from Papaya’s team to arrange them.

Papaya is also a vehicle and fleet management platform, enabling fleet operators to streamline their operations by directly interacting with all their service providers from a single platform. With data analytics, and maintenance capabilities, it enables real-time monitoring of vehicle and hub performance, simplifies ticket creation and allows fleet managers to anticipate downtime.

With Papaya, you can find the perfect cargo bikes for your fleet and optimise the way you manage them. You minimise costs, increase uptime, and improve the availability of cargo bikes.

The cheat sheet to find the perfect commercial electric cargo bike for your fleet

Make an Informed Decision

In conclusion, when choosing electric cargo bikes for your fleet, it is crucial to consider the specific needs and requirements of your operations. Not all electric cargo bikes are the same, and a strategic approach is necessary. Prioritising safety, stability, and ergonomics is essential for the well-being of riders and the protection of cargo.

Thorough research, testing, and evaluation of options, along with a consideration of financial aspects, will lead to the selection of the ideal electric cargo bikes that optimise fleet performance and contribute to long-term success in sustainable transportation solutions.

And don’t forget, Papaya can accompany you along your journey! Contact us now for more information.